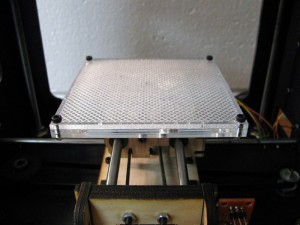

A member at the hackerspace donated a Cricut 6" cutter when she upgraded to the Expression model. I've seen these little devices in most craft stores and even Wal-mart, and they seem ripe for the hacking. The Cricut line of personal CNC paper cutters appear to have been looked into on a number of occasions from what I could find, but I didn't really find any good resources for information on hardware hacking other than a couple simple hacks and the discovery that the Cricut USB link was actually an USB to RS232 connection. I also didn't find any open source or homebrew software to turn these devices from advanced scrapbook die cutters to general purpose CNC paper cutter/plotter/whatever. I really want to play around with this thing (including trying to mount a spindle on it for crude PCB routing, among other things), but it looks like someone still needs to do a little leg work to make that happen easily.

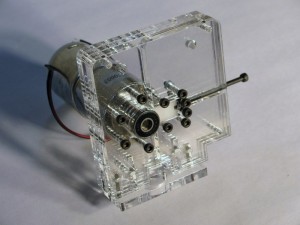

What I did find is that there are a few proprietary software packages out there ( and ) that allow you to place and cut TrueType fonts and SVG format vector graphics. This coupled with the fact that the device was using an RS232 link to do the actual communication to the on board microcontroller led me to believe it should be trivial to back-engineer the command protocol. I downloaded the trial versions of the available 3rd party tools and grabbed a few windows serial port sniffing applications and set off to start logging communications.

Unfortunately I found that no combination of serial sniffer and control software seemed to work out. I can easily use the serial sniffers to look at the transactions of the Arduino bootloader and the host application over the USB to RS232 link, but I see no activity with the 3rd party Cricut software. I can set up a USB sniffer link and log data, but these logs are relatively verbose and I'd like to use a more elegant solution to log the RS232 data directly.

Since I'm more comfortable with the hardware side of things, I'm currently focusing on the problem from that angle. I didn't want to start chopping up the space's Cricut, I set out to acquire my own for the task. I managed to scoop one up for $60 with no cartridges from an individual who upgraded to the Expression as well. Stay tuned for some hardware dissection notes as I take my personal unit apart!