So apparently it's a really bad idea to use aluminum mesh as a container for active carbon! After sitting around for a couple weeks the aluminum screen became extremely brittle after reacting with the active carbon and the whole thing sorta fell apart. I'm going to probably be replacing the mesh cage with a basket made from perforated stainless steal when I've got some free time, after the most likely.

Archive for May, 2012

The Carbon Filter Experiment Postmortem

Wednesday, May 30th, 2012Adding Colored Etching to Laser Cut Parts

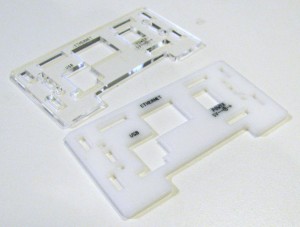

Saturday, May 12th, 2012So while making the rubber band gun business cards, I stumbled upon a good method for inking laser etched text and graphics. Basically, after vector etching some graphics into a laser cut part you can blot a dry erase marker over your etching and let it wick into the lines put down by the laser:

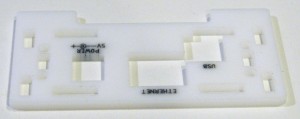

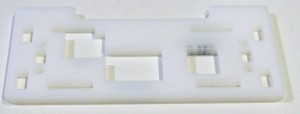

After letting the ink dry you can wipe the excess ink on the surface away to reveal your etched graphics and text. This seems to work great with Delrin as well as acrylic (with a few caveats):

The white acrylic part showed a little crazing (cracking) when I applied the dry erase marker around the "Power" text, so I really let it soak in the ink so see what would happen:

This crazing only occurred on the "Power" text, leading me to believe that it was caused because of its proximity to the laser cut edge. Annealing the acrylic after cutting could resolve this issue, but there's also the possibility that the white acrylic was extruded rather than cast which wouldn't help either. The clear acrylic was cast and it didn't show signs of additional crazing when exposed to the dry erase marker.

Obviously you can't do this with anything too porous that would absorb the dry erase ink outright, but it should work on a reasonable number of laserable materials. Additionally raster etching probably won't work too well with this method, but it might be wroth a try.