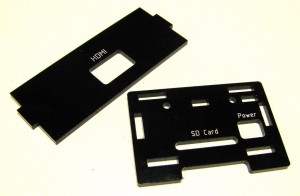

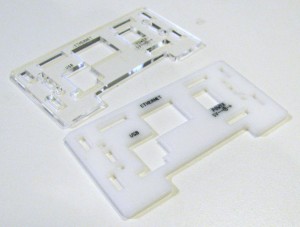

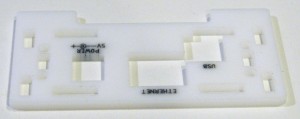

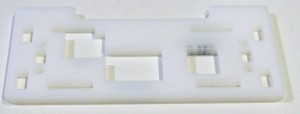

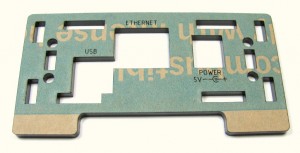

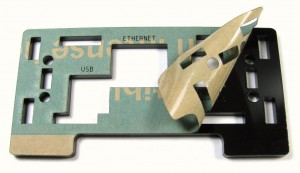

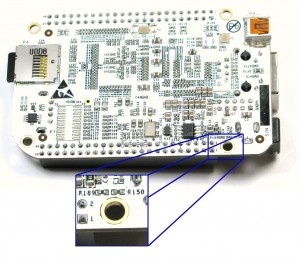

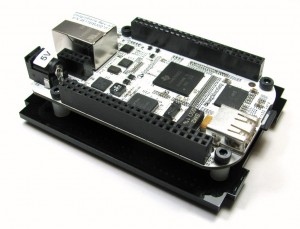

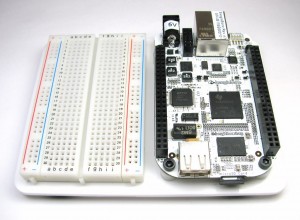

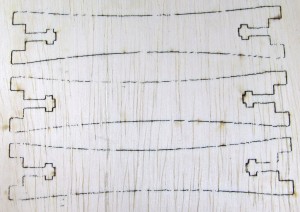

So one of the problems with the Raspberry Pi board is the lack of mounting options simply because it doesn't have any mounting holes. A few nice injection molded enclosures for the Pi and other boards out there use a simple clips to hold PCBs in place, eliminating the need for additional hardware. I figured there should be a good, easy to make solution out there for those of us that can't get injection molded parts on a whim so came up with some nice laser cut Delrin clips that can be used with typical laser cut mounts (see above pic). Here's a video of the clips in action on a prototype Raspberry Pi sled I'm working on:

As you can see, they're pretty easy to use with a properly designed mount plate. There's a couple advantages the clips have over the standard bolt, standoff, nut mounting method. First, you don't have to have all the additional hardware bits, just some Delrin stock. Second, they make assembly pretty easy with no juggling of bolts and standoffs on boards (if you've mounted a PCB before, you're probably had the moment you realize you didn't hold one of the bolts in place as you flip the board over to tighten everything down as miscellaneous hardware bits fly everywhere). Third, you can make the standoffs a specific height if you need to easily since you're not limited to the standard heights that are available.

You can grab the files for my Raspberry Pi sled reference design on my page if you want to try them out for yourself!

I've also got them in my store !