I haven't been posting any projects, but I've definitely been working on stuff! If you don't follow my Thingiverse posts, I've leaned a little about character modeling in Blender and made me a ceiling cat for the shop:

I also made some spools for jumper wire that fit in my trusty electronics tackle boxes:

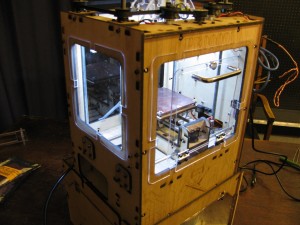

I've also been working on a set of parts that'll attach to a standard Cupcake CNC to add fume hood functionality for a fellow Makerbot operator. It's not done yet, but the parts I have done make it look like a little oven, which I think is pretty awesome:

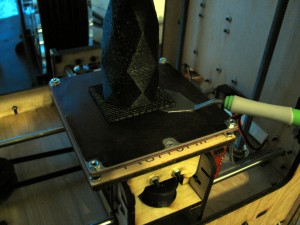

I've also been working on the CNC router at CCCKC, which has had a few successful test cuts and should help me finish a few long-running projects I've had on the back burner. Check out this for video and some more info.

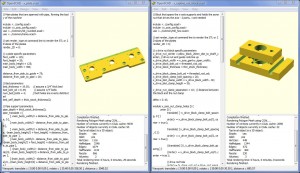

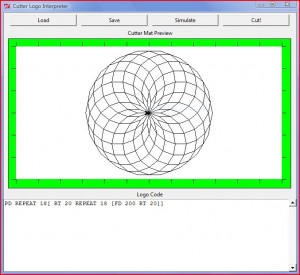

Lastly, I've been working on my self replicating CNC project again. I've decided to make this project even more ambitious and I've acquired most of the hardware that I think I'll need to finish it up, or at least get it off it's feet. I'm also learning OpenSCAD and doing all my initial design and prototyping in OpenSCAD. I'm going to try and use OpenSCAD to model all the milled components in 3D and then use OpenSCAD's 2D rendering capabilities to generate the DXF files that will eventually be used to generate tool paths to actually mill the parts. I'm trying to make the design very parametric and well organized so it'll be easy for me to tweak and easy for others to modify use the parts they have on hand or make new derivatives. The CCCKCCNC being up should help prototyping as well.