Another fun hack you can do by modifying the guts of a servo is converting the controller on board to a brushed DC motor controller. The resulting controller will work just like a standard RC speed controller, allowing you to make a DC motor turn forward or reverse with it's speed proportional to the throttle position on your RC setup. A simple controller like this should work great if you're trying to throw together a small RC setup like the from some scavenged parts.

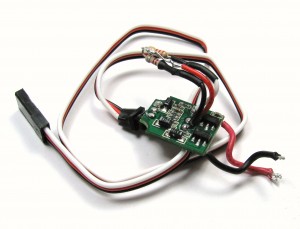

All you need to do to build your controller is remove the controller of a standard servo and replace the potentiometer with two equal value resistors (typically 2.2k, but higher values should be OK) and hook up the brushed motor you want to control in place of the servo's DC motor. You want to connect the two resistors in the center by twisting their leads together connect the outside leads of the resistors to the outside potentiometer terminals and the twisted center to the center terminal. Here's a pic of a controller (specifically the TGY-S4505B controller, see some more pics of the guts of this servo in my previous post) after it's been removed from the servo and the resistors have been installed:

I used heat shrink on the two outside leads of the resistor to keep the connections insulated. Next I put heat shrink over the two resistors:

I used heat shrink on the two outside leads of the resistor to keep the connections insulated. Next I put heat shrink over the two resistors:

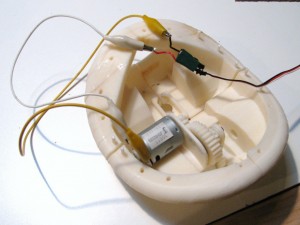

And tape everything down. Now I'm ready to test it out on ' partially completed using a standard RC Tx/Rx set by connecting up the DC motor I want to power where the servo's DC motor was previously connected:

If everything works you should not see the DC motor turn (or turn very slowly until you adjust the trim) when applying power to the RC Tx/Rx set but the brushed DC motor should respond as expected when you use the throttle on your controller. If you've modified a servo for continuous rotation this should be very familiar to you because that's essentially what you've done, you're just not using the mechanics of the servo.