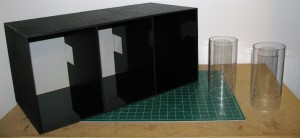

Above is a picture of a recent project I did for a client that wanted a custom enclosure for some experiments with mice. It's constructed from laser cut ABS sheets and held together with screws, but it doesn't use the now somewhat ubiquitous T-slot construction used in many laser cut enclosures. Because ABS isn't extremely brittle like acrylic and doesn't have a grain or laminate layers like wood, you can simply screw it together without significantly effecting structural integrity if you do it right.

(Safety Note: This should go without saying, but if you're cutting ABS, properly handle the fumes! You need a properly sized carbon filter on your exhaust and you need to have adequate air flow. Additionally the parts should be left to outgas in a well ventilated area for at least 24 hours after cutting!)

I first used the method I'll be outlining here to construct a "dark box" add on for a piece of lab equipment. It had to fit very snugly inside an existing box, not let light through, and not provide climbing holds for the mice under test. I didn't want to end up gluing everything together (I'm glad I didn't, I had to modify the setup for an additional experiment later), and T-slot and bracket based attachment methods were not ideal.

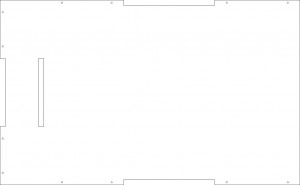

First off, in my enclosure design I've added tabs to ease alignment of all the connecting parts. If done correctly, tabs will prevent you from assembling your enclosure incorrectly and allow you to quickly align edges of parts you're screwing together. Tabs also allow you to insert screws into both of the parts you're joining perpendicularly, which a regular butt joint wouldn't allow you to do. I use 1/2 inch #4 flat head sheet metal for 1/4" ABS. I drill a 3/32" pilot hole is drilled into the parts that will be joined. Pilot holes are a must, as you can drive a screw in to ABS with a little work, but you'll see stress lines and bulging, if not outright splitting of the plastic if you don't use an appropriately sized pilot hole. I place the pilot holes at design time and cut them into the part so I have a nice guide when it comes time to drill. Here's an example of a part with tabs and pilot holes in place:

To make sure I hit the correct depth, I add some tape to the bit to let me know I've drilled far enough into the piece.

I use right angle clamps to hold the parts I'm joining in place while drilling.

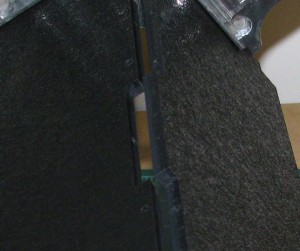

Here's a close up of the tabs and pilot holes after they've been drilled:

Next I countersink the holes and install the #4 screws:

You can prep and screw a side together relatively quickly with a little practice. Once you've got a few sides on your enclosure, you can rely less on clamping parts together and simply hold down the panel you're installing with one hand while drilling with the other (assuming you've added tabs to your parts so they align properly and stay in place).

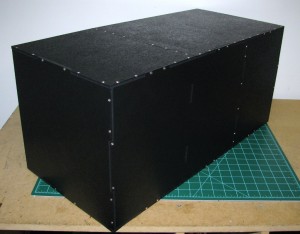

Here's some pics of the finished product:

I've also used black oxide coated screws with this method to make the final enclosure look a little cleaner as well. Overall I like the look of this method over T-slot construction for some projects since you don't have to oversize some parts to accommodate the tabs and screw holes and the joints seem a little sturdier as well.

Tags: ABS, Laser Cut, Laser Cutter